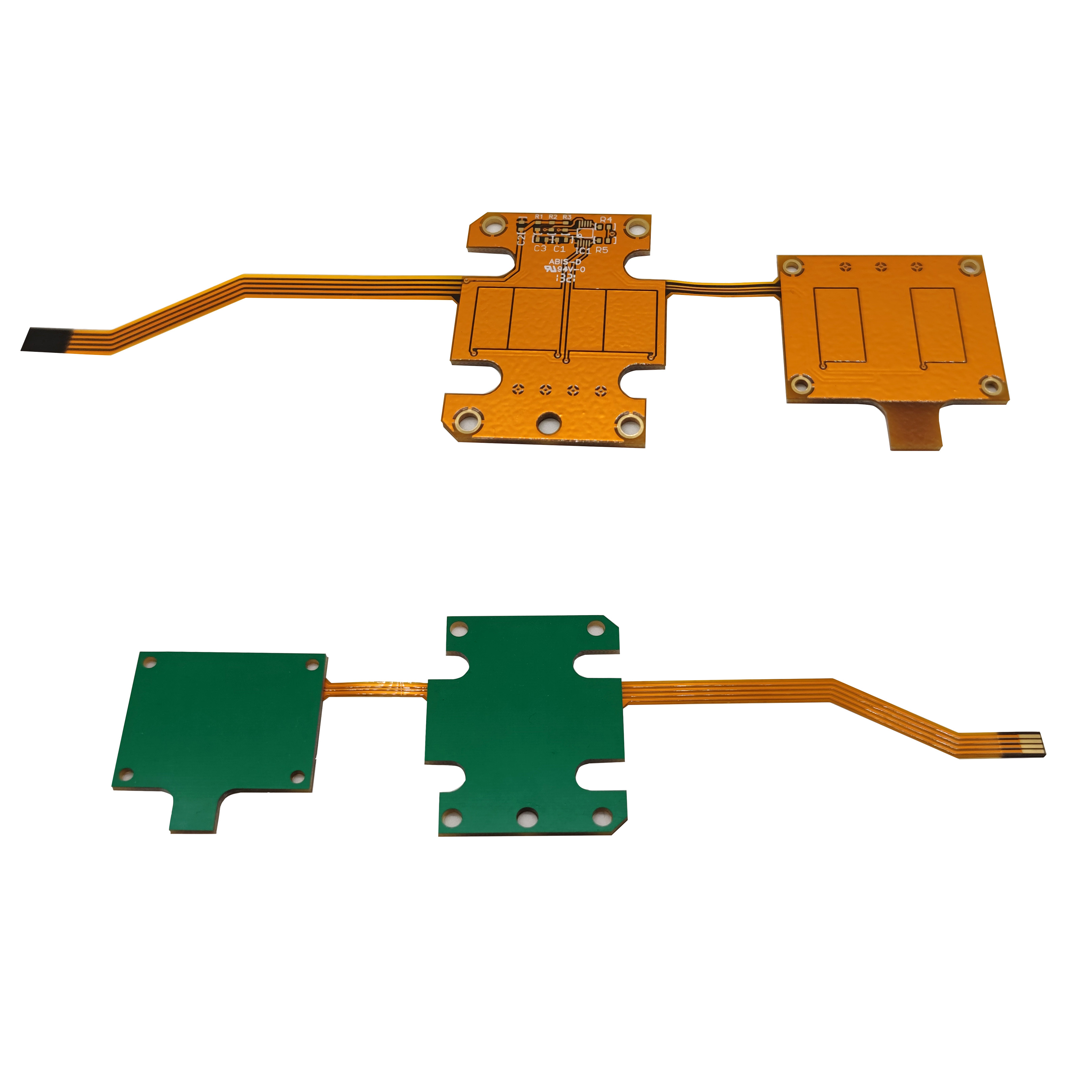

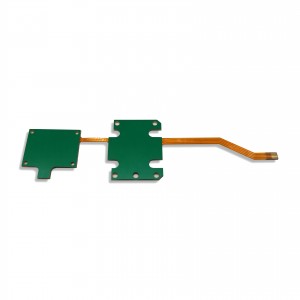

2 txheej Custom PI Stiffeners Flexible Printed Circuit Boards PCBs

Cov ntaub ntawv yooj yim

| Qauv No. | PCB-A42 |

| Thauj pob | Nqus Ntim |

| Daim ntawv pov thawj | UL, ISO9001 & ISO14001, RoHS |

| Daim ntawv thov | Cov khoom siv hluav taws xob |

| Qhov tsawg kawg nkaus / Kab | 0.075mm / 3mil |

| Muaj Peev Xwm Ntau Lawm | 720,000 M2 / Xyoo |

| HS Code | 853400900 ib |

| Keeb kwm | Ua nyob rau hauv Suav teb |

Product Description

Flexible printed circuit board saib xyuas

Txhais

Flexible PCB - Flexible Printed Circuit, hu ua FPC.

Ib qho yooj yim luam tawm Circuit Court tuaj yeem txhais tau tias yog ib qho kev nthuav qhia ntawm cov kab hluav taws xob txuas nrog rau ntawm lub substrate hloov tau.Nws yog tsim rau hauv cov qauv hluav taws xob hluav taws xob siv cov qauv teeb pom kev hloov pauv thiab cov txheej txheem etching ntawm qhov chaw ntawm lub substrate hloov tau yooj yim.

Yam ntxwv

Flex circuits dav siv hauv xov tooj ntawm tes, koob yees duab thiab ntsehnav tau.

Nws tuaj yeem ua kom muaj peev xwm ua tau zoo nyob rau hauv qhov chaw ntau dua li cov khoom siv nruj nruj. Cov kab hluav taws xob hloov tau yooj yim kuj muaj qhov ua tau zoo dua rau qhov kub thiab txias, kev poob siab thiab kev co.nws muaj kev ua tau zoo nrog kev tsim cov kev sib tw xws li: kev sib tw tsis tuaj yeem, cov kev xav tau tshwj xeeb impedance, tshem tawm cov lus sib tham, ntxiv kev tiv thaiv thiab kev tiv thaiv siab.

Muab faib

Ib sab flex PCB

Ib sab flex nrog dualnkag mus

Ob chav sided flex PCB

Multi-layer flex PCB

Technical & Peev xwm

| Yam khoom | Tshwj xeeb. |

| Txheej | 1 ~ 8 |

| Board Thickness | 0.1mm-0.2 hli |

| Cov khoom siv substrate | PI (0.5mil, 1mil, 2mil), tus tsiaj (0.5mil, 1mil) |

| Conductive Medium | Copper ntawv ci (1/3oz, 1/2oz, 1oz, 2oz) Constantan Silver Paste Tooj Ink |

| Max Vaj Huam Sib Luag Loj | 600mm × 1200mm |

| Min Qhov Loj | 0.1 hli |

| Min Kab Dav / Qhov Chaw | 3mil (0.075 hli) |

| Maximposition loj (ib zaug & ob lub vaj huam sib luag) | 610mm * 1200mm (Txoj kev txwv) 250mm * 35mm (tsuas yog tsim cov qauv kuaj) |

| Qhov siab tshaj plaws qhov loj me (ib lub vaj huam sib luag & ob lub vaj huam sib luag tsis muaj PTH tus kheej ziab tus number case + UV lub teeb khoom) | 610 * 1650 hli |

| Drilling qhov (Mechanical) | 17-175 Nws |

| Finish Hole (Mechanical) | 0.10mm-6.30 hli |

| Txoj kab uas hla Tolerance (Mechanical) | 0.05 hli |

| Kev Sau Npe (Mechanical) | 0.075 hli |

| Aspect Ratio | 2: 1 (Qhov tsawg kawg nkaus aperture 0.1mm) 5: 1 (Qhov tsawg kawg nkaus aperture 0.2mm) 8: 1 (Qhov tsawg kawg nkaus aperture 0.3mm) |

| SMT Mini.Solder Mask Dav | 0.075 hli |

| Mini.Solder Mask Clearance | 0.05 hli |

| Impedance Control kam rau ua | 士10% |

| Nto tiav | ENIG, HASL, Chem.Tin/Sn |

| Solder mask/Protective Film | PI (0.5mil, 1mil, 2mil) (Daj, Dawb, Dub) PET (1mil, 2mil) Solder mask (ntsuab, daj, dub...) |

| Silkscreen | Liab / Daj / Dub / Dawb |

| Daim ntawv pov thawj | UL, ISO 9001, ISO14001, IATF16949 |

| Thov tshwj xeeb | Glue(3M467,3M468,3M9077,TESA8853...) |

| Cov khoom siv | Shengyi, ITEQ, Taiyo, thiab lwm yam. |

| Ntim Pob | Nqus + Carton |

| Lub hli ntau lawm / m² | 60,000 m² |

Flexible PCB Lead Time

| Batch me meNtim ≤ 1 m² | Hnub Ua Haujlwm | Kev tsim khoom loj | Hnub Ua Haujlwm |

| Ib leeg | 3-4 | Ib leeg | 8-10 |

| 2-4 txheej | 4-5 | 2-4 txheej | 10-12 |

| 6-8 txheej | 10-12 | 6-8 txheej | 14-18 |

Yuav Ua Li Cas ABIS Deal With Flexible PCB Issues?

Thawj qhov uas peb paub tseeb yog cov cuab yeej tsim nyog los tsim koj lub rooj tsavxwm.Tom qab ntawd, cov neeg ua haujlwm tau ntsib txaus los daws qhov kev sib tw ntawm kev tsim cov rooj sib txig sib luag.

Qhib lub qhov ncauj qhov ntswg los yog overlay txaus-sib txawv cov kauj ruam ntawm cov txheej txheem yuav hloov li cas ib tug saj zawg zog board zoo li.Etching thiab plating tuaj yeem kho cov duab ntawm PCB, uas yog vim li cas koj yuav tsum xyuas kom meej tias qhov qhib qhov rooj yog qhov dav haum.

Xaiv cov ntaub ntawv kom zoo, tseem xav txog lwm yam, xws li qhov loj, qhov hnyav, thiab kev ntseeg siab ntawm lub rooj tsavxwm.

Tswj kom tsim nyog qhov sib thooj ntawm cov pob qij txha thiab khoov taw tes - qhov sib koom ua ke yuav tsum nyob ntawm qhov xav tau deb ntawm qhov chaw khoov.Yog tias koj muab lawv kaw dhau lawm, delamination lossis tawg solder ncoo yuav tshwm sim.

Tswj Solder pad spacing - ABIS kom ntseeg tau tias muaj qhov chaw txaus ntawm cov ntaub qhwv thiab cov kab hluav taws xob nyob ib sab ntawm lawv, kom tsis txhob lamination poob.

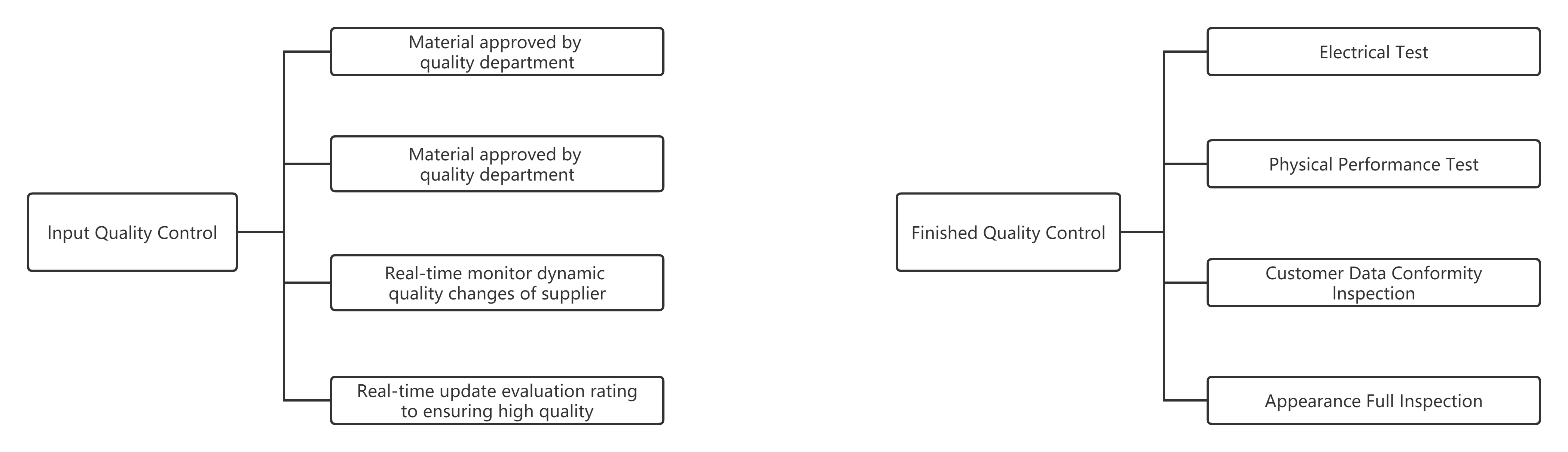

ABIS Lub Hom Phiaj Zoo

Tus nqi dhau ntawm cov khoom nkag siab tshaj 99.9%, tus naj npawb ntawm cov kev tsis lees paub ntau hauv qab 0.01%.

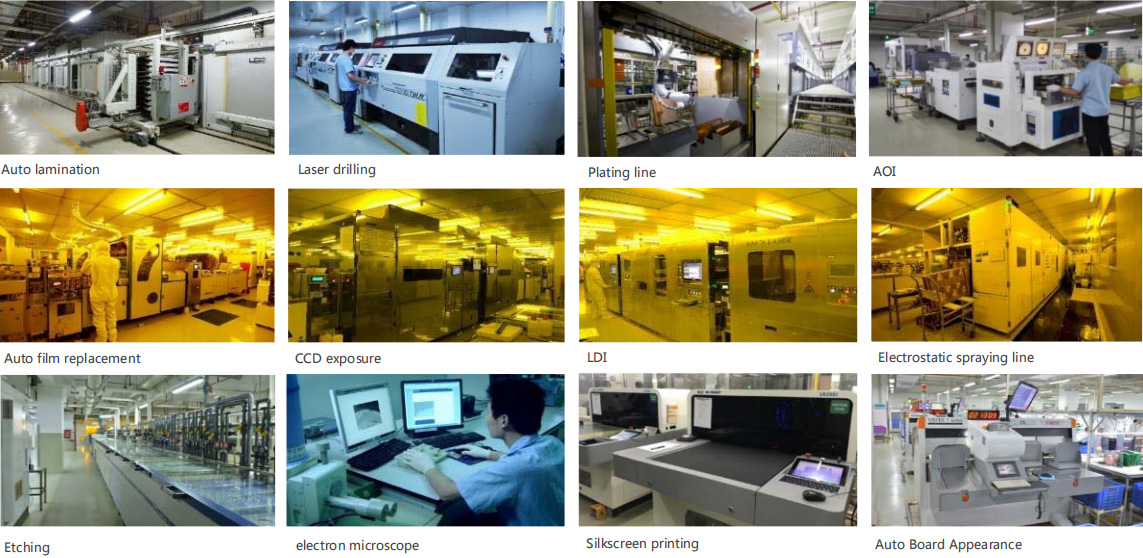

ABIS cov chaw muaj ntawv pov thawj tswj txhua qhov txheej txheem tseem ceeb kom tshem tawm txhua yam teeb meem ua ntej tsim khoom.

ABIS siv cov software siab heev los ua qhov kev soj ntsuam DFM dav dav ntawm cov ntaub ntawv tuaj, thiab siv cov kev tswj xyuas zoo tshaj plaws thoob plaws hauv kev tsim khoom.

ABIS ua 100% kev pom thiab AOI tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab kuaj, insulating resistance test thiab ionic cleanliness test.

Daim ntawv pov thawj

FAQ

Txhua tus neeg siv khoom yuav muaj kev muag khoom los tiv tauj koj.Peb lub sijhawm ua haujlwm: AM 9:00-PM 19:00 (Beijing Time) txij hnub Monday txog Friday.Peb yuav teb koj email sai li sai tau thaum lub sijhawm ua haujlwm.Thiab koj kuj tuaj yeem tiv tauj peb cov muag khoom hauv xov tooj yog tias ceev.

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallograghic microscope

f), AOI (Automated Optical Inspection)

Feem ntau 2-3 hnub rau kev ua qauv.Lub sij hawm ua cov khoom loj yuav nyob ntawm qhov kev txiav txim kom muaj nuj nqis thiab lub caij koj tso qhov kev txiav txim.

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallograghic microscope

f), AOI (Automated Optical Inspection)

ABIS tsis muaj MOQ txwv rau PCB lossis PCBA.

ABLS ua 100% kev pom thiab AOl tshuaj xyuas nrog rau kev kuaj hluav taws xob, ntsuas hluav taws xob siab,impedance tswjkuaj, micro-sectioning, thermal shock testing, solder testing, kev ntseeg siab kuaj, insulating resistance testing, ionic cleanliness kuajthiab PCBA Functional testing.

Thov xa cov lus nug rau peb, xws li Yam Khoom Naj Npawb, Ntau Yam rau txhua yam khoom, Kev thov zoo, Logo, Cov nqe lus them nqi, txoj kev thauj mus los, Qhov chaw tso tawm, thiab lwm yam. Peb yuav ua cov lus hais meej meej rau koj sai li sai tau.

Tus nqi xa khoom raws sijhawm yog ntau dua 95%

a), 24 teev ceev tig rau ob sab qauv PCB

b), 48hours rau 4-8 khaubncaws sab nraud povtseg PCB

c), 1 teev rau kev hais lus

d), 2 teev rau cov lus nug engineer / Cov lus tsis txaus siab

e), 7-24 teev rau kev txhawb nqa kev pabcuam / xaj kev pabcuam / kev tsim khoom lag luam

| Muaj peev xwm ntawm cov khoom kub muag | |

| Ob Chav Sab / Multilayer PCB Rhiav | Aluminium PCB Rhiav |

| Kev muaj peev xwm | Kev muaj peev xwm |

| Cov khoom siv raw: CEM-1, CEM-3, FR-4 (High TG), Rogers, TELFON | Cov khoom siv raw: Aluminium puag, tooj liab puag |

| Txheej: 1 txheej rau 20 Txheej | Txheej: 1 txheej thiab 2 txheej |

| Min. kab dav / qhov chaw: 3mil / 3mil (0.075mm / 0.075mm) | Min. kab dav / qhov chaw: 4mil / 4mil (0.1mm / 0.1mm) |

| Min.Qhov loj: 0.1mm (drilling qhov) | Min.Qhov Loj: 12mil (0.3mm) |

| Max.Board loj: 1200mm * 600mm | Max.Board loj: 1200mm * 560mm (47in * 22in) |

| Tiav board thickness: 0.2mm-6.0mm | Ua tiav board thickness: 0.3 ~ 5mm |

| Copper foil thickness: 18um ~ 280um (0.5oz ~ 8oz) | Copper foil thickness: 35um ~ 210um (1oz ~ 6oz) |

| NPTH qhov kam rau ua: +/- 0.075mm, PTH qhov kam rau ua: +/- 0.05mm | Qhov chaw kam rau ua: +/- 0.05mm |

| Kev Ua Tau Zoo: +/- 0.13mm | Routing outline kam rau ua: +/ 0.15mm;punching outline kam rau ua: +/ 0.1mm |

| Nto tiav: Lead-free HASL, immersion kub (ENIG), immersion nyiaj, OSP, kub plating, kub ntiv tes, Carbon INK. | Nto tiav: Lead dawb HASL, immersion kub (ENIG), immersion nyiaj, OSP thiab lwm yam |

| Impedance tswj kam rau ua: +/- 10% | Nyob twj ywm thickness kam rau ua: +/- 0.1mm |

| Muaj peev xwm tsim tau: 50,000 sqm / hli | MC PCB Muaj peev xwm ntau lawm: 10,000 sqm / hli |