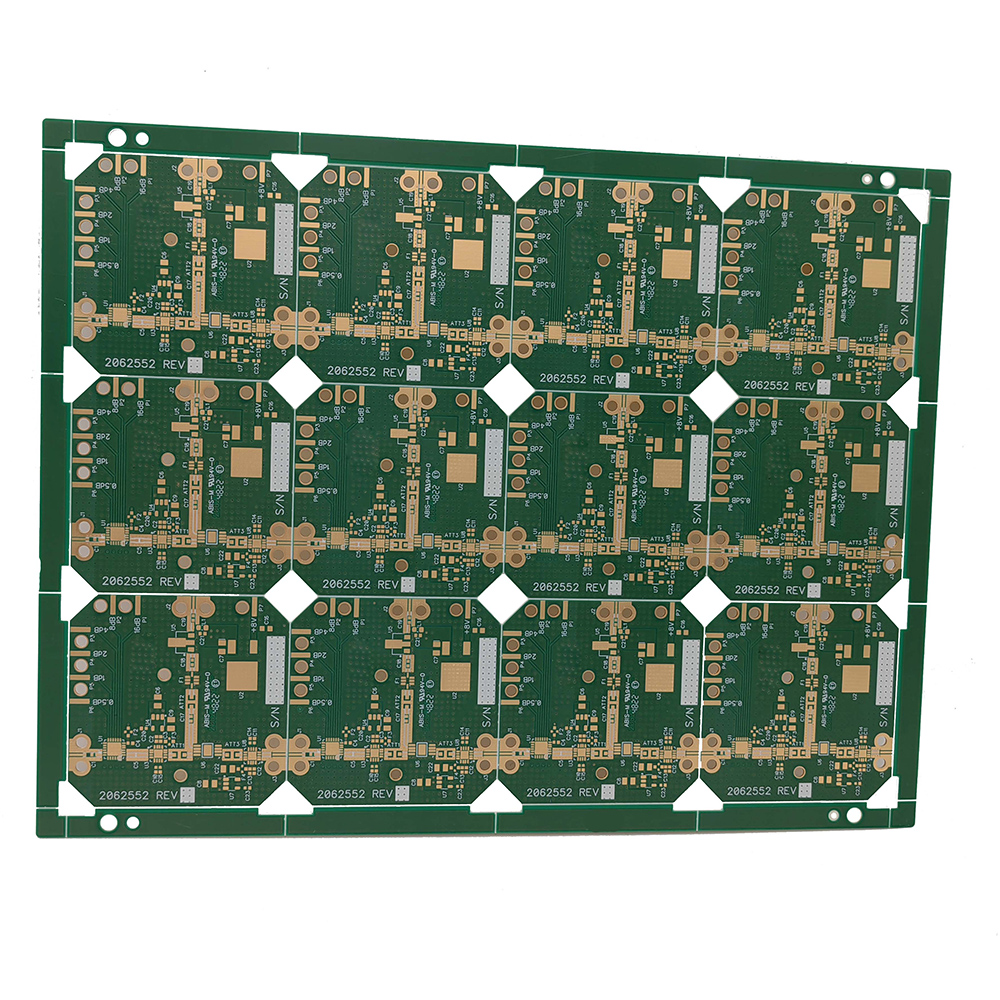

3oz Multilayer Rigid Circuit Board nyob rau hauv ENIG PCB Manufacturing Tuam Tshoj tsum

Cov ntaub ntawv yooj yim

| Qauv No. | PCB-A10 |

| Thauj pob | Nqus Ntim |

| Daim ntawv pov thawj | UL, ISO9001 & ISO14001, RoHS |

| Daim ntawv thov | Cov khoom siv hluav taws xob |

| Qhov tsawg kawg nkaus / Kab | 0.075mm / 3mil |

| Muaj Peev Xwm Ntau Lawm | 50,000 sqm / hli |

| HS Code | 853400900 ib |

| Keeb kwm | Ua nyob rau hauv Suav teb |

Product Description

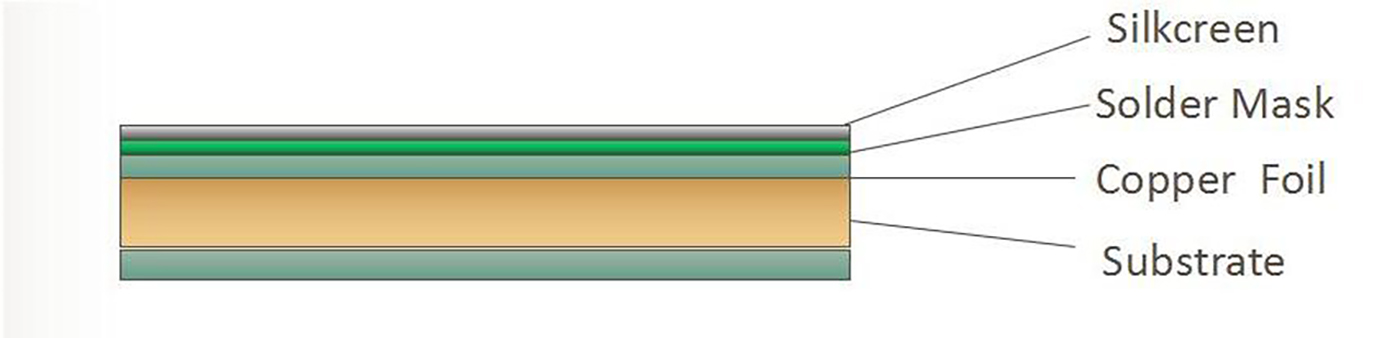

FR4 PCB Taw qhia

FR txhais tau hais tias "nplaim hluav taws xob," FR-4 (lossis FR4) yog qib NEMA rau cov khoom siv iav-reinforced epoxy laminate, cov khoom sib xyaw ua ke ntawm cov ntaub fiberglass nrog epoxy resin binder uas ua rau nws zoo tagnrho substrate rau cov khoom siv hluav taws xob. nyob rau ntawm lub rooj tsavxwm luam tawm.

Pros thiab Cons ntawm FR4 PCB

Cov khoom siv FR-4 yog qhov nrov heev vim nws muaj ntau yam zoo kawg nkaus uas tuaj yeem muaj txiaj ntsig zoo rau cov ntawv luam tawm.Ntxiv rau qhov pheej yig thiab yooj yim ua haujlwm nrog, nws yog ib qho hluav taws xob insulator nrog lub zog dielectric siab heev.Tsis tas li ntawd, nws yog ruaj, noo-resistant, kub-resistant thiab hnav.

FR-4 yog cov khoom siv dav dav, feem ntau nrov rau nws cov nqi qis thiab cov neeg kho tshuab thiab hluav taws xob ruaj khov.Thaum cov khoom siv no muaj cov txiaj ntsig zoo thiab muaj ntau yam tuab thiab qhov ntau thiab tsawg, nws tsis yog qhov kev xaiv zoo tshaj plaws rau txhua daim ntawv thov, tshwj xeeb tshaj yog cov ntawv siv zaus xws li RF thiab microwave tsim.

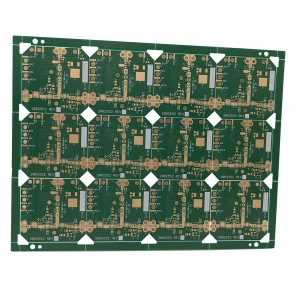

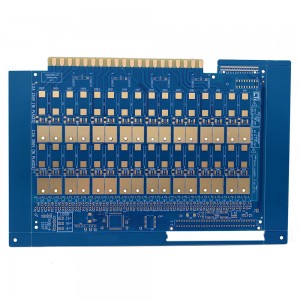

Multi-layer PCB Structure

Multilayer PCBs ntxiv qhov nyuaj thiab ceev ntawm PCB tsim los ntawm kev ntxiv cov txheej txheem ntxiv tshaj li saum toj thiab hauv qab cov khaubncaws sab nraud povtseg pom nyob rau hauv ob sab boards.Multilayer PCBs yog tsim los ntawm laminating ntau txheej.Cov txheej txheej sab hauv, feem ntau yog ob sab ntawm lub rooj sib tham, tau muab sib dhos ua ke, nrog cov txheej txheem insulating nyob nruab nrab ntawm thiab nruab nrab ntawm cov ntawv tooj liab rau cov txheej txheej.Qhov drilled los ntawm lub rooj tsavxwm (vias) yuav ua rau kev sib txuas nrog cov txheej txheem sib txawv ntawm lub rooj tsavxwm.

Technical & Peev xwm

| Yam khoom | Muaj Peev Xwm Ntau Lawm |

| Txheej suav | 1-20 txheej |

| Khoom siv | FR-4, CEM-1 / CEM-3, PI, Siab Tg, Rogers, PTEF, Alu / Cu Base, thiab lwm yam |

| Board thickness | 0.10mm-8.00 hli |

| Qhov Loj tshaj plaws | 600mm X 1200mm |

| Board Outline Tolerance | + 0.10 hli |

| Thickness kam rau ua (t≥0.8mm) | ± 8% |

| Thickness kam rau ua (t <0.8mm) | ± 10% |

| Rwb thaiv tsev txheej Thickness | 0.075mm-5.00 hli |

| Yam tsawg kawg kab | 0.075 hli |

| Qhov chaw tsawg kawg nkaus | 0.075 hli |

| Tawm Txheej Copper Thickness | 18-350 Nws |

| Inner Layer Copper Thickness | 17-175 Nws |

| Drilling qhov (Mechanical) | 0.15mm-6.35 hli |

| Finish qhov (Mechanical) | 0.10mm-6.30 hli |

| Txoj kab uas hla Tolerance (Mechanical) | 0.05 hli |

| Kev Sau Npe (Mechanical) | 0.075 hli |

| Aspect Ratio | 16:1 |

| Solder Mask Hom | LPI |

| SMT Mini.Solder Mask Dav | 0.075 hli |

| Mini.Solder Mask Clearance | 0.05 hli |

| Plug Qhov Diameter | 0.25mm-0.60 hli |

| Impedance tswj kam rau ua | ± 10% |

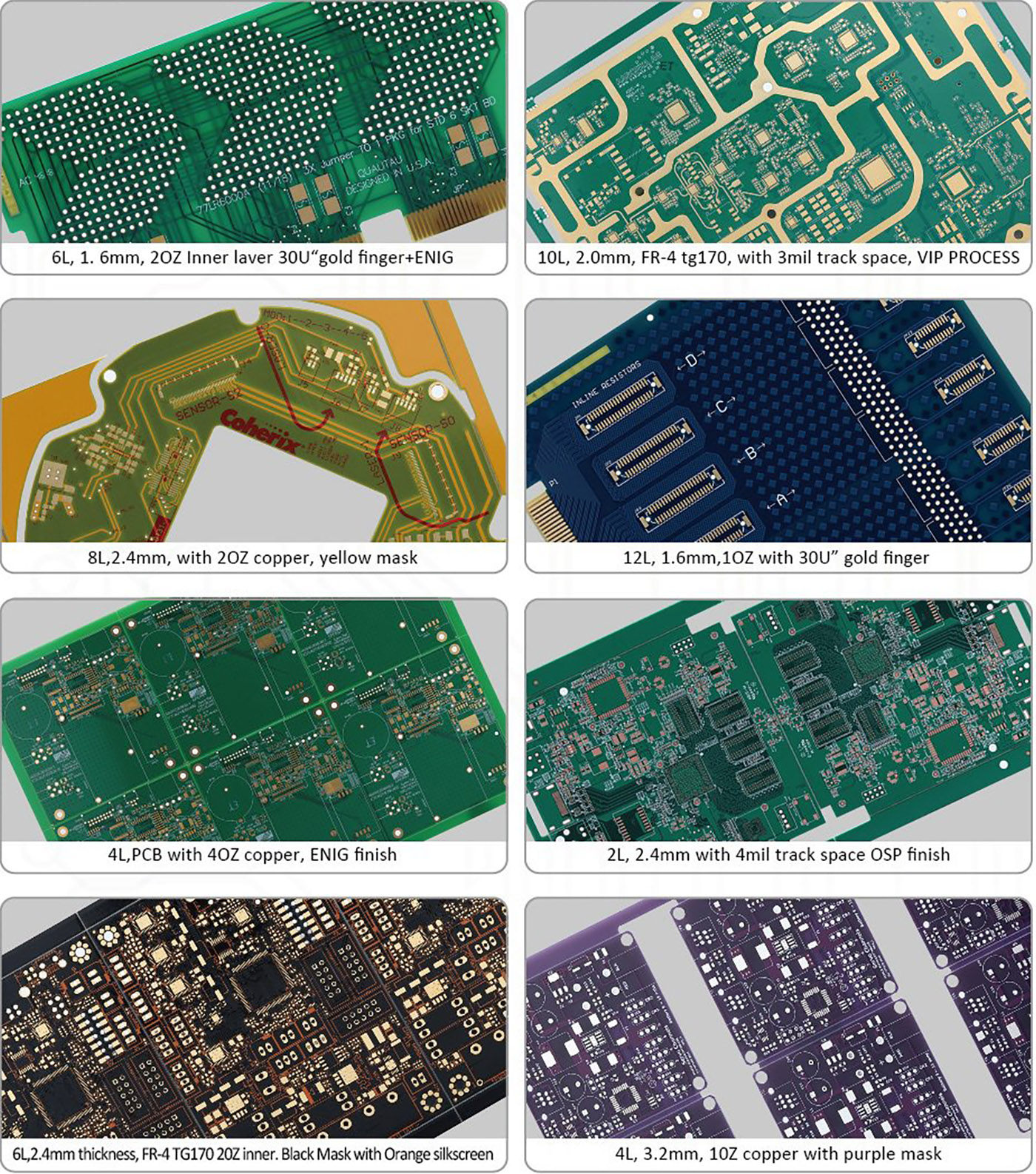

| Nto tiav / kho | HASL, ENIG, Chem, Tin, Flash Kub, OSP, Kub ntiv tes |

Cov khoom siv resin tuaj qhov twg hauv ABIS?

Feem ntau ntawm lawv los ntawm Shengyi Technology Co., Ltd. (SYTECH), uas yog lub ntiaj teb thib ob loj tshaj plaws CCL chaw tsim tshuaj paus nyob rau hauv cov nqe lus ntawm kev muag khoom ntim, los ntawm 2013 mus rau 2017. Peb tsim kev sib raug zoo mus sij hawm ntev ntawm kev koom tes txij li thaum 2006. Lub FR4 resin khoom. (Model S1000-2, S1141, S1165, S1600) feem ntau yog siv los ua ib leeg thiab ob sab ntawv luam tawm Circuit Board nrog rau ntau txheej boards.Nov yog cov lus qhia rau koj siv.

Rau FR-4: Sheng Yi, King Board, Nan Ya, Polycard, ITEQ, ISOLA

Rau CEM-1 & CEM 3: Sheng Yi, King Board

Rau High Frequency: Sheng Yi

Rau UV kho: Tamura, Chang Xing (* Muaj xim: Ntsuab) Solder rau ib sab

Rau Liquid Diam duab: Tao Yang, Resist (Wet Film)

Chuan Yu (* Muajxim: Dawb, xav tau Solder Yellow, Ntshav, Liab, Xiav, Ntsuab, Dub)

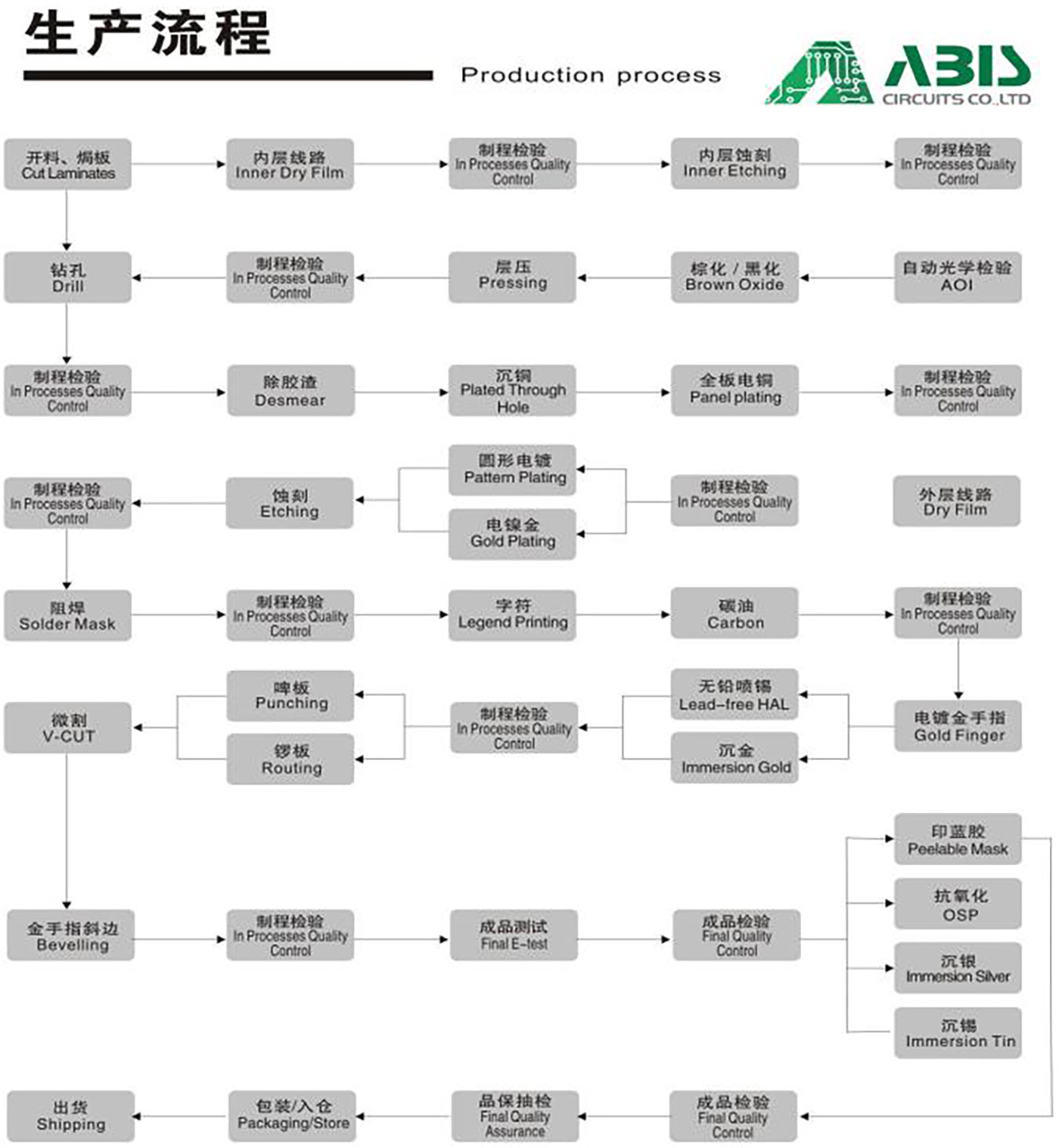

Txheej txheem ntau lawm PCB

Cov txheej txheem pib nrog tsim Layout ntawm PCB siv cov PCB tsim software / CAD Tool (Proteus, Eagle, lossis CAD).

Tag nrho cov seem ntawm cov kauj ruam yog kev tsim cov txheej txheem ntawm Rigid Printed Circuit Board yog tib yam li Ib Sab PCB lossis Ob Chav Sided PCB lossis Multi-layer PCB.

Q/T Lub Sijhawm Ua Haujlwm

| Qeb | Lub Sijhawm Lead sai tshaj plaws | Lub Sijhawm Lead |

| Ob sab | 24 teev | 120 teev |

| 4 Txheej | 48h ib | 172h ua |

| 6 Txheej | 72h ua | 192h ua |

| 8 Txheej | 96h ib | 212h ib |

| 10 Txheej | 120 teev | 268h ua |

| 12 Txheej | 120 teev | 280h ib |

| 14 Txheej | 144h ib | 292h ua |

| 16-20 Txheej | Nyob ntawm cov kev xav tau tshwj xeeb | |

| Tshaj 20 Layers | Nyob ntawm cov kev xav tau tshwj xeeb | |

ABIS 'txav mus tswj FR4 PCBS

Qhov Kev Npaj

Tshem tawm cov khib nyiab kom zoo & kho lub tshuab laum tsis zoo: ua ntej plating los ntawm tooj liab, ABIS them nyiaj siab rau txhua qhov ntawm FR4 PCB kho kom tshem tawm cov khib nyiab, qhov tsis sib xws, thiab epoxy smear, cov qhov huv si xyuas kom cov plating ua tiav rau ntawm phab ntsa ntawm lub qhov. .kuj, thaum ntxov ntawm cov txheej txheem, laum tshuab tsis tau kho kom raug.

Kev npaj nto

Deburring ua tib zoo: peb cov neeg ua haujlwm paub txog technology yuav paub ua ntej tias tib txoj hauv kev kom tsis txhob muaj qhov tshwm sim tsis zoo yog xav tias yuav tsum muaj kev tuav tshwj xeeb thiab ua cov kauj ruam tsim nyog kom paub tseeb tias cov txheej txheem ua tib zoo thiab raug.

Thermal Expansion Rates

Ua raws li kev soj ntsuam nrog ntau yam ntaub ntawv, ABIS yuav tuaj yeem txheeb xyuas qhov sib xyaw ua ke kom paub tseeb tias nws tsim nyog.tom qab ntawd ua kom muaj kev ntseeg siab ntev ntev ntawm CTE (coefficient ntawm thermal expansion), nrog rau qis CTE, qhov tsawg dua cov plated los ntawm qhov yuav ua tsis tiav los ntawm kev rov flexing ntawm tooj liab uas ua rau cov txheej txheem sab hauv.

Scaling

ABIS tswj lub circuitry yog scaled-up los ntawm cov feem pua paub nyob rau hauv kev cia siab ntawm qhov kev poob no kom cov khaubncaws sab nraud povtseg yuav rov qab mus rau lawv raws li-tsim qhov ntev tom qab lub lamination voj voog tiav.kuj, siv lub laminate chaw tsim tshuaj paus lub hauv paus scaling cov lus pom zoo ua ke nrog nyob rau hauv-lub tsev statistical txheej txheem tswj cov ntaub ntawv, mus dial-nyob rau hauv scale yam uas yuav zoo ib yam nyob rau hauv lub sij hawm nyob rau hauv uas tej chaw tsim khoom.

Tshuab dhos

Thaum lub sijhawm los tsim koj lub PCB, ABIS nco ntsoov tias koj xaiv muaj cov cuab yeej zoo thiab kev paub los tsim kom raug ntawm thawj zaug sim.

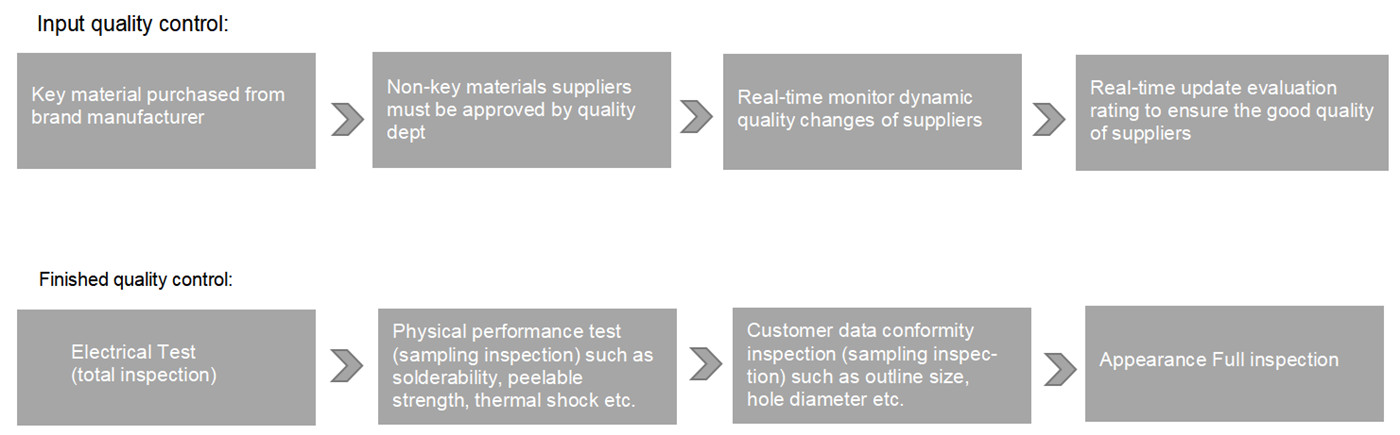

ABIS Lub Hom Phiaj Zoo

Tus nqi dhau ntawm cov khoom nkag siab tshaj 99.9%, tus naj npawb ntawm cov kev tsis lees paub ntau hauv qab 0.01%.

ABIS cov chaw muaj ntawv pov thawj tswj txhua qhov txheej txheem tseem ceeb kom tshem tawm txhua yam teeb meem ua ntej tsim khoom.

ABIS siv cov software siab heev los ua qhov kev soj ntsuam DFM dav dav ntawm cov ntaub ntawv tuaj, thiab siv cov kev tswj xyuas zoo tshaj plaws thoob plaws hauv kev tsim khoom.

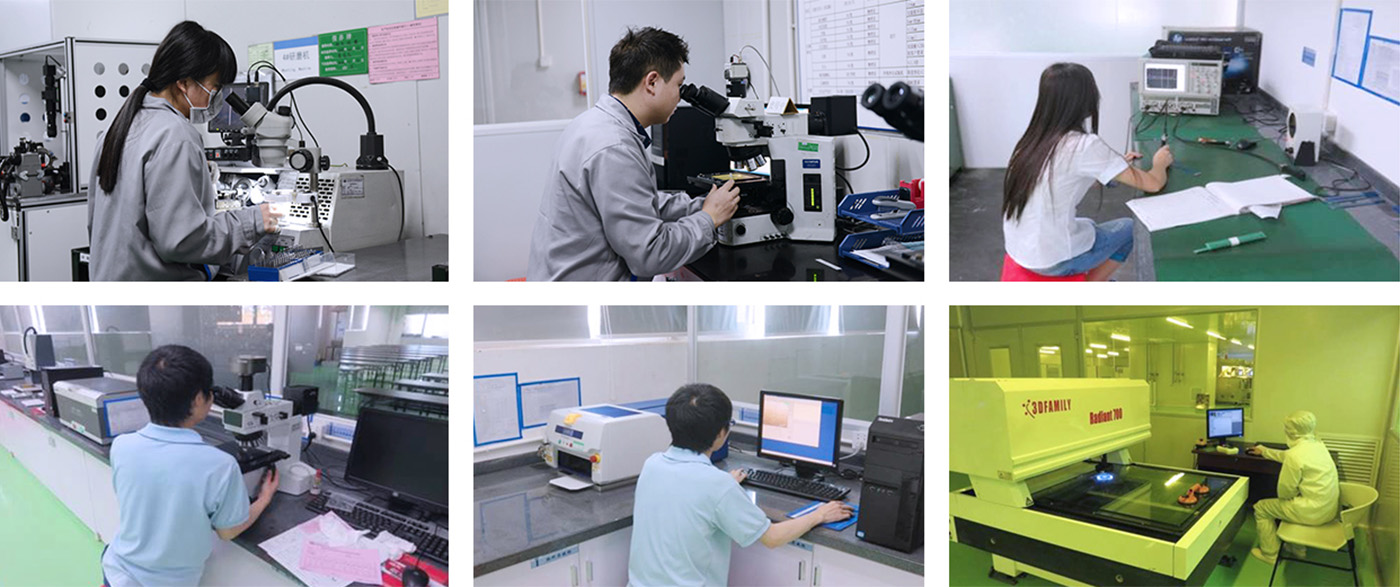

ABIS ua 100% kev pom thiab AOI tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab kuaj, insulating resistance test thiab ionic cleanliness test.

Daim ntawv pov thawj

Dab tsi yog qhov zoo ntawm kev tsim khoom hauv ABIS?

Saib ncig koj.Yog li ntau cov khoom tuaj ntawm Tuam Tshoj.Pom tseeb, qhov no muaj ntau yam laj thawj.Nws tsis yog tus nqi xwb.

Kev npaj cov lus hais yog ua tiav sai.

Kev txiav txim ntau lawm yog ua tiav sai.Koj tuaj yeem npaj cov lus txiav txim rau lub hlis ua ntej, peb tuaj yeem npaj lawv tam sim ntawd thaum PO tau lees paub.

Cov saw hlau tau nthuav dav heev.Tias yog vim li cas peb tuaj yeem yuav txhua yam khoom siv los ntawm tus khub tshwj xeeb sai heev.

Cov neeg ua haujlwm yooj yim thiab mob siab rau.Yog li ntawd, peb lees txais txhua qhov kev txiav txim.

24 kev pabcuam online rau kev xav tau ceev.Lub sijhawm ua haujlwm ntawm +10 teev ib hnub.

Cov nqi qis dua.Tsis muaj tus nqi zais.Txuag rau cov neeg ua haujlwm, nyiaj siv ua haujlwm thiab logistics.

FAQ

Txhawm rau kom paub meej qhov kev tsocai raug, nco ntsoov suav nrog cov ntaub ntawv hauv qab no rau koj qhov project:

Ua kom tiav GERBER cov ntaub ntawv suav nrog cov npe BOM

l Ntau

l Tig sijhawm

l Panelization Requirements

l Cov ntaub ntawv xav tau

l Ua kom tiav cov cai

l Koj qhov kev cai tsocai yuav raug xa hauv 2-24 teev, nyob ntawm tus qauv tsim.

Tshawb xyuas hauv 12 teev.Thaum Engineer cov lus nug thiab cov ntaub ntawv ua haujlwm tau kuaj xyuas, peb yuav pib tsim khoom.

ISO9001, ISO14001, UL USA & USA Canada, IFA16949, SGS, RoHS daim ntawv qhia.

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallo graghic microscope

f), AOI (Automated Optical Inspection)

Yog lawm, peb txaus siab muab cov qauv coj mus kuaj thiab kuaj xyuas qhov zoo, sib xyaw qauv txiav txim muaj.Thov nco ntsoov tus neeg yuav khoom yuav tsum them tus nqi thauj khoom.

Tus nqi xa khoom raws sijhawm yog ntau dua 95%

a), 24 teev ceev tig rau ob sab qauv PCB

b), 48hours rau 4-8 khaubncaws sab nraud povtseg PCB

c), 1 teev rau kev hais lus

d), 2 teev rau cov lus nug engineer / Cov lus tsis txaus siab

e), 7-24 teev rau kev txhawb nqa kev pabcuam / xaj kev pabcuam / kev tsim khoom lag luam

ABIS yeej tsis xaiv qhov kev txiav txim.Ob qho kev txiav txim me me thiab kev txiav txim loj tau txais tos thiab Peb ABIS yuav ua tib zoo thiab lub luag haujlwm, thiab pab cov neeg siv khoom zoo thiab kom muaj nuj nqis.

ABLS ua 100% kev pom thiab AOl tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab, kev ntsuas kev tiv thaiv insulating, ionic cleanliness test thiab PCBA Functional testing.

a), 1 Teev cov lus hais

b), 2 teev ntawm kev tsis txaus siab tawm tswv yim

c), 7 * 24 teev kev txhawb nqa

d), 7 * 24 xaj kev pabcuam

e), 7 * 24 teev kev xa khoom

f), 7 * 24 ntau lawm khiav

| Muaj peev xwm ntawm cov khoom kub muag | |

| Ob Chav Sab / Multilayer PCB Rhiav | Aluminium PCB Rhiav |

| Kev muaj peev xwm | Kev muaj peev xwm |

| Cov khoom siv raw: CEM-1, CEM-3, FR-4 (High TG), Rogers, TELFON | Cov khoom siv raw: Aluminium puag, tooj liab puag |

| Txheej: 1 txheej rau 20 Txheej | Txheej: 1 txheej thiab 2 txheej |

| Min. kab dav / qhov chaw: 3mil / 3mil (0.075mm / 0.075mm) | Min. kab dav / qhov chaw: 4mil / 4mil (0.1mm / 0.1mm) |

| Min.Qhov loj: 0.1mm (drilling qhov) | Min.Qhov Loj: 12mil (0.3mm) |

| Max.Board loj: 1200mm * 600mm | Max.Board loj: 1200mm * 560mm (47in * 22in) |

| Tiav board thickness: 0.2mm-6.0mm | Ua tiav board thickness: 0.3 ~ 5mm |

| Copper foil thickness: 18um ~ 280um (0.5oz ~ 8oz) | Copper foil thickness: 35um ~ 210um (1oz ~ 6oz) |

| NPTH qhov kam rau ua: +/- 0.075mm, PTH qhov kam rau ua: +/- 0.05mm | Qhov chaw kam rau ua: +/- 0.05mm |

| Kev Ua Tau Zoo: +/- 0.13mm | Routing outline kam rau ua: +/ 0.15mm;punching outline kam rau ua: +/ 0.1mm |

| Nto tiav: Lead-free HASL, immersion kub (ENIG), immersion nyiaj, OSP, kub plating, kub ntiv tes, Carbon INK. | Nto tiav: Lead dawb HASL, immersion kub (ENIG), immersion nyiaj, OSP thiab lwm yam |

| Impedance tswj kam rau ua: +/- 10% | Nyob twj ywm thickness kam rau ua: +/- 0.1mm |

| Muaj peev xwm tsim tau: 50,000 sqm / hli | MC PCB Muaj peev xwm ntau lawm: 10,000 sqm / hli |