Customized Wearable 4 Layers Rigid-Flex PCB Circuit Board Tuam Tshoj FPC

Cov ntaub ntawv yooj yim

| Qauv No. | PCB-A6 |

| Thauj pob | Nqus Ntim |

| Daim ntawv pov thawj | UL, ISO9001 & ISO14001, RoHS |

| Qhov tsawg kawg nkaus / Kab | 0.075mm / 3mil |

| Tswj impedance | 100 ± 10% |

| Muaj Peev Xwm Ntau Lawm | 720,000 M2 / Xyoo |

| Keeb kwm | Ua nyob rau hauv Suav teb |

| Daim ntawv thov | Cov khoom siv hluav taws xob |

Product Description

Yuav ua li cas ABIS tuav lub Rigid-Flexible Circuit Court?

Lub peev xwm los tsim cov kev sib dhos zaum kawg ntawm cov PCBs nruj thiab hloov tau yooj yim kom haum rau cov khoom ntim khoom yog qhov tseem ceeb ntawm cov khoom siv hluav taws xob hloov tau yooj yim.Nov yog 2 lub tswv yim los koom nrog hauv koj qhov kev tsim qauv nruj-flex:

Ua kom muaj kev ntseeg tau ntau ntxiv: Cov dabtsi yog khoov uas flex circuits endure txhais tau hais tias cov tooj liab feem ntau yuav delaminate dua li ntawm lub rooj tsavxwm nruj.Qhov sib ntxiv ntawm tooj liab rau lub substrate yog tsawg dua ntawm FR4 PCB ib yam nkaus.

Txhim kho cov kab thiab vias nrog teardrops: Yog tias tsis tswj tau, khoov lub substrate tuaj yeem ua rau delamination thiab cov khoom tsis ua haujlwm.Cov kab thiab vias tuaj yeem, txawm li cas los xij, ntxiv dag zog rau kev tiv thaiv delamination, kuj tsim cov txiaj ntsig zoo dua hauv kev tsim khoom los ntawm kev muab ntau dua drilling kam rau ua.

Technical & Peev xwm

| Yam khoom | Spec. |

| Txheej | 1 ~ 8 |

| Board Thickness | 0.1mm-8.0 hli |

| Khoom siv | Polymide, PET, PEN, FR4 |

| Max Vaj Huam Sib Luag Loj | 600mm × 1200mm |

| Min Qhov Loj | 0.1 hli |

| Min Kab Dav / Qhov Chaw | 3mil (0.075 hli) |

| Board Outline Tolerance | 0.10 hli |

| Rwb thaiv tsev txheej Thickness | 0.075mm-5.00 hli |

| Thaum kawg Thickness | 0.0024 ''-0.16 '' (0.06-2.4.00mm) |

| Drilling qhov (Mechanical) | 17-175 Nws |

| Finish Hole (Mechanical) | 0.10mm-6.30 hli |

| Txoj kab uas hla Tolerance (Mechanical) | 0.05 hli |

| Kev Sau Npe (Mechanical) | 0.075 hli |

| Aspect Ratio | 16:1 |

| Solder Mask Hom | LPI |

| SMT Mini.Solder Mask Dav | 0.075 hli |

| Mini.Solder Mask Clearance | 0.05 hli |

| Plug Qhov Diameter | 0.25mm-0.60 hli |

| Impedance Control kam rau ua | 士10% |

| Nto tiav | ENIG, Chem.Tin/Sn, Flash Kub |

| Solder daim npog qhov ncauj | Ntsuab / Daj / Dub / Dawb / Liab / Xiav |

| Silkscreen | Liab / Daj / Dub / Dawb |

| Daim ntawv pov thawj | UL, ISO 9001, ISO14001, IATF16949 |

| Thov tshwj xeeb | Qhov muag qhov muag, Kub ntiv tes, BGA, Carbon number case, peekable daim npog qhov ncauj, VIP txheej txheem, Ntug plating, Ib nrab qhov |

| Cov khoom siv | Shengyi, ITEQ, Taiyo, thiab lwm yam. |

| Ntim Pob | Nqus + Carton |

Flexible PCB Lead Time

| Batch me meNtim ≤ 1 m² | Hnub Ua Haujlwm | Kev tsim khoom loj | Hnub Ua Haujlwm |

| Ib leeg | 3-4 | Ib leeg | 8-10 |

| 2-4 txheej | 4-5 | 2-4 txheej | 10-12 |

| 6-8 txheej | 10-12 | 6-8 txheej | 14-18 |

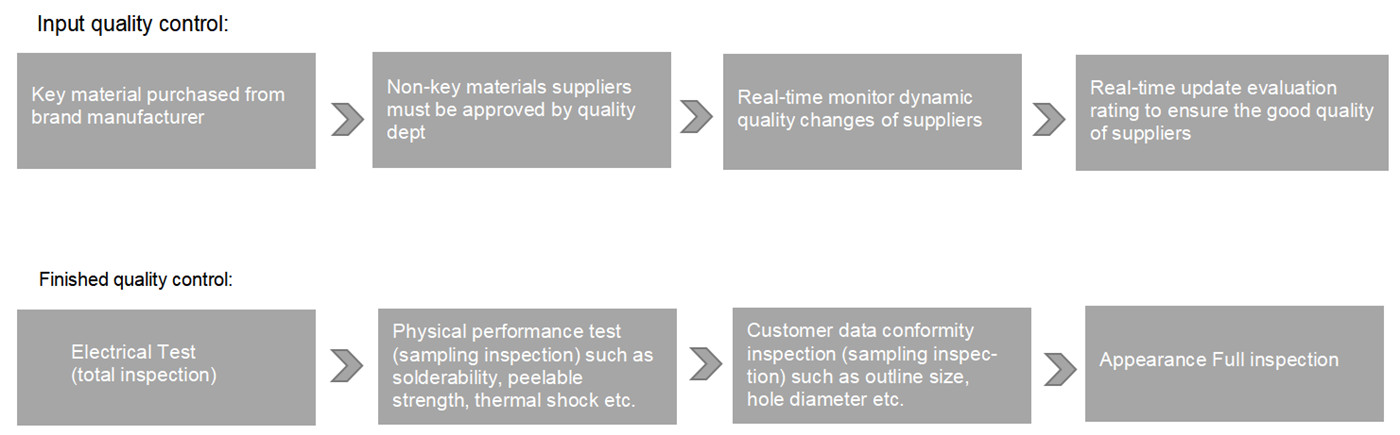

ABIS Lub Hom Phiaj Zoo

Tus nqi dhau ntawm cov khoom nkag siab tshaj 99.9%, tus naj npawb ntawm cov kev tsis lees paub ntau hauv qab 0.01%.

ABIS cov chaw muaj ntawv pov thawj tswj txhua qhov txheej txheem tseem ceeb kom tshem tawm txhua yam teeb meem ua ntej tsim khoom.

ABIS siv cov software siab heev los ua qhov kev soj ntsuam DFM dav dav ntawm cov ntaub ntawv tuaj, thiab siv cov kev tswj xyuas zoo tshaj plaws thoob plaws hauv kev tsim khoom.

ABIS ua 100% kev pom thiab AOI tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab kuaj, insulating resistance test thiab ionic cleanliness test.

Technology Road Map

| Technology | 2019 | 2020 | 2021 |

| Txheej | 20 | 26 | 32 |

| Max board thickness mm | 6 | 7 | 8 |

| Min board thickness mm | 0.4 | 0.3 | 0.2 |

| Max vaj huam sib luag loj / pcs loj mm | 610 * 910 / 580 * 850 | 620 * 1000 / 580 * 950 | 620 * 1000 / 580 * 950 |

| Min Core thickness mm (tsis muaj tooj liab) | 0.075 ib | 0.05 Nws | 0.05 Nws |

| Max tooj liab thickness oz | Sab hauv txheej: 5oz; Tawm txheej: 6 oz | Sab hauv txheej: 6oz; Tawm txheej: 10oz | Pem hauv ntej: 6 oz Tawm txheej: 10oz |

| Min dav / qhov chaw μm | 75/75 ib | 65/65 ib | 50/50 |

| Min Mec qhov mm | 0.20 ib | 0.15 | 0.15 |

| Min Laser Drilling μm | 75 | 75 | 65 |

| Aspect ratio | 13:1 | 16:1 | 16:1 |

| MAX HDI Aspect ratio | 0.8:1 ib | 1: 1 | 1: 1 |

| Kev sau npe ntawm cov khaubncaws sab nraud povtseg (≥10L) μm | 125 | 100 | 76 |

| Kev ywj pheej tswj kam rau ua | ± 10% | ± 8% | ± 8% |

| Rov qab xyaum μm | ± 75 | ± 75 | ± 75 |

| txheej txheem tshwj xeeb | POFV (VIPPO), Siab RF | ||

| Nto tiav | ENIG, kub plating, HASL (HF), OSP, Immersion tin, Immersion nyiaj | ||

Daim ntawv pov thawj

FAQ

Txhua tus neeg siv khoom yuav muaj kev muag khoom los tiv tauj koj.Peb lub sijhawm ua haujlwm: AM 9:00-PM 19:00 (Beijing Time) txij hnub Monday txog Friday.Peb yuav teb koj email sai li sai tau thaum lub sijhawm ua haujlwm.Thiab koj kuj tuaj yeem tiv tauj peb cov muag khoom hauv xov tooj yog tias ceev.

Cov neeg muab khoom tseem ceeb (FR4): Kingboard (Hong Kong), NanYa (Taiwan), thiab Shengyi (Tuam Tshoj), Yog tias lwm tus, thov RFQ.

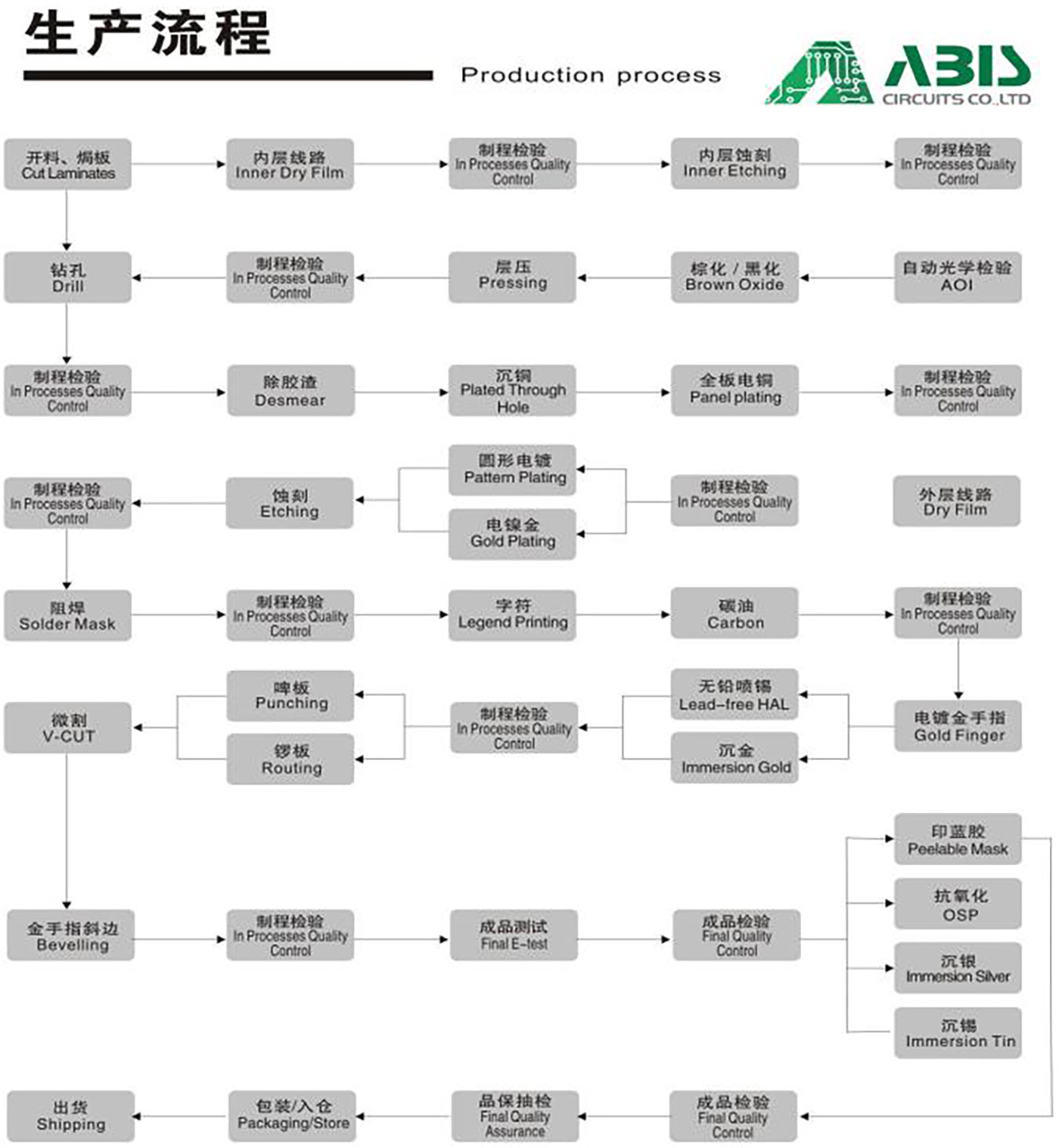

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallograghic microscope

f), AOI (Automated Optical Inspection)

Feem ntau 2-3 hnub rau kev ua qauv.Lub sij hawm ua cov khoom loj yuav nyob ntawm qhov kev txiav txim kom muaj nuj nqis thiab lub caij koj tso qhov kev txiav txim.

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallograghic microscope

f), AOI (Automated Optical Inspection)

ISO9001, ISO14001, UL USA & USA Canada, IFA16949, SGS, RoHS daim ntawv qhia.

ABLS ua 100% kev pom thiab AOl tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab, kev ntsuas kev tiv thaiv insulating, ionic cleanliness test thiab PCBA Functional testing.

Thov xa cov lus nug rau peb, xws li Yam Khoom Naj Npawb, Ntau Yam rau txhua yam khoom, Kev thov zoo, Logo, Cov nqe lus them nqi, txoj kev thauj mus los, Qhov chaw tso tawm, thiab lwm yam. Peb yuav ua cov lus hais meej meej rau koj sai li sai tau.

Tus nqi xa khoom raws sijhawm yog ntau dua 95%

a), 24 teev ceev tig rau ob sab qauv PCB

b), 48hours rau 4-8 khaubncaws sab nraud povtseg PCB

c), 1 teev rau kev hais lus

d), 2 teev rau cov lus nug engineer / Cov lus tsis txaus siab

e), 7-24 teev rau kev txhawb nqa kev pabcuam / xaj kev pabcuam / kev tsim khoom lag luam