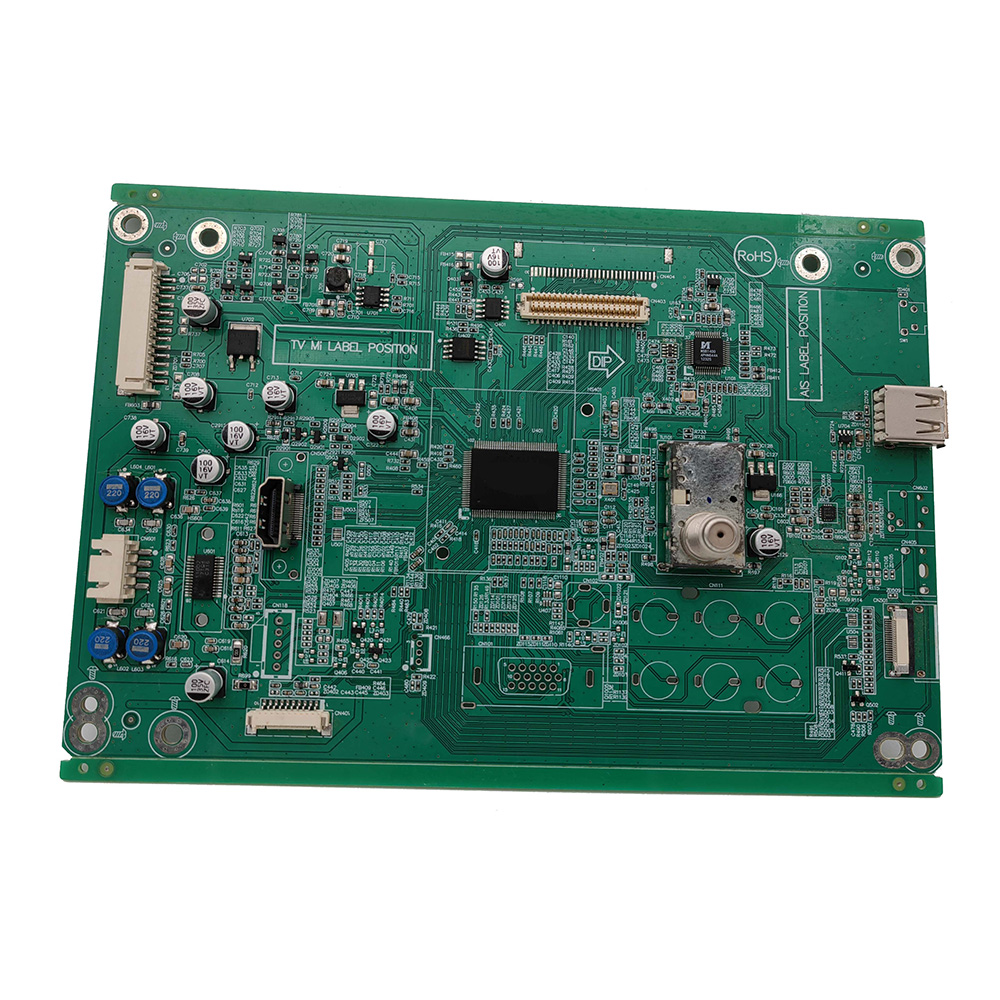

Tig-key 4 khaubncaws sab nraud povtseg PCB los ua ke Board Zoo FR4 Multilayer PCBA

Cov ntaub ntawv tsim khoom

| Qauv No. | PCB-A3 |

| Thauj pob | Nqus Ntim |

| Daim ntawv pov thawj | UL, ISO9001 & ISO14001, RoHS |

| Lus txhais | IPC Chav Kawm 2 |

| Qhov tsawg kawg nkaus / Kab | 0.075mm / 3mil |

| Keeb kwm | Ua nyob rau hauv Suav teb |

| Muaj Peev Xwm Ntau Lawm | 720,000 M2 / Xyoo |

| Daim ntawv thov | Consumer Electronics |

Product Description

PCBA Projects Taw Qhia

ABIS CIRCUITS Lub Tuam Txhab xa cov kev pabcuam, tsis yog cov khoom lag luam nkaus xwb.Peb muab kev daws teeb meem, tsis yog khoom xwb.

Los ntawm PCB ntau lawm, cov khoom yuav khoom mus rau cov khoom sib dhos.Xws li:

Kev cai PCB

PCB kos duab / tsim raws li koj daim duab schematic

PCB kev tsim khoom

Kev tsim khoom siv

PCB sib dhos

PCBA 100% xeem

Peb Qhov Zoo

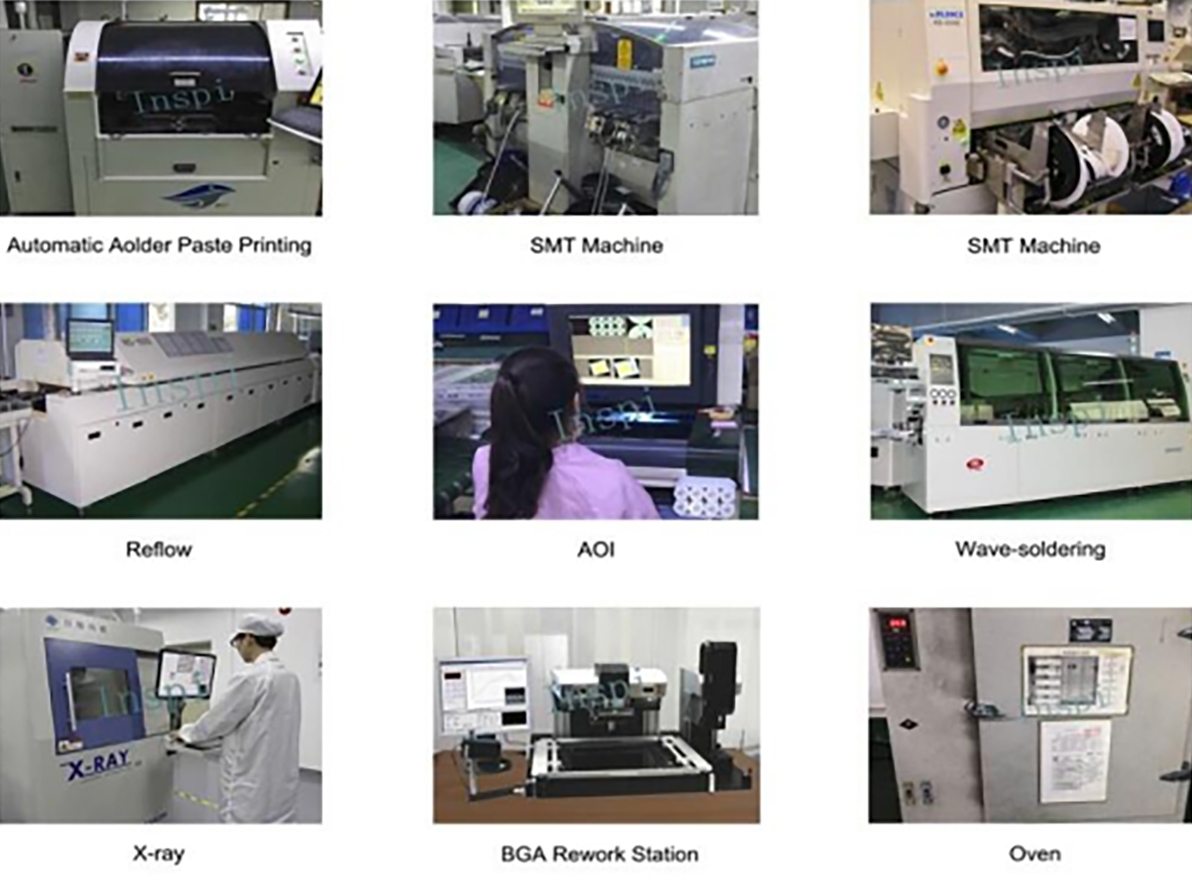

Cov cuab yeej siv siab-siab ceev xaiv thiab qhov chaw tshuab uas tuaj yeem ua haujlwm txog 25,000 SMD cov khoom hauv ib teev

Cov khoom muaj peev xwm ua tau zoo 60K Sqm txhua hli-Muab cov ntim qis thiab kev xav tau ntawm PCB ntau lawm, kuj tseem ua cov khoom loj

Cov kws tshaj lij engineering pab pawg-40 engineers thiab lawv tus kheej lub tsev cuab yeej, muaj zog ntawm OEM.Muaj ob txoj kev xaiv yooj yim: Kev Cai thiab Txuj Ci-In-depth paub txog IPC Chav Kawm II thiab III Cov Qauv

Peb muab cov kev pabcuam EMS dav dav rau cov neeg siv khoom uas xav kom peb sib sau ua ke PCB rau hauv PCBA, suav nrog cov qauv qauv, NPI project, ntim me me thiab nruab nrab.Peb kuj tuaj yeem muab txhua yam khoom siv rau koj qhov kev sib dhos PCB.Peb cov engineers thiab pab neeg muab khoom muaj kev paub dhau los hauv cov saw hlau thiab EMS kev lag luam, nrog kev paub tob hauv SMT sib dhos tso cai los daws txhua qhov teeb meem tsim khoom.Peb cov kev pabcuam yog tus nqi-zoo, hloov tau, thiab txhim khu kev qha.Peb tau txaus siab rau cov neeg siv khoom thoob plaws ntau qhov kev lag luam suav nrog kev kho mob, kev lag luam, tsheb thiab cov neeg siv khoom siv hluav taws xob.

Muaj peev xwm PCBA

| Muaj peev xwm |

|

| Ib leeg thiab ob sab SMT / PTH | Yog lawm |

| Qhov loj ntawm ob sab, BGA ntawm ob sab | Yog lawm |

| Qhov tsawg tshaj plaws Chips loj | 0201 ib |

| Min BGA thiab Micro BGA pitch thiab pob suav | 0.008 in. (0.2mm) suab, pob suav ntau dua 1000 |

| Min Leaded qhov chaw pitch | 0.008 nti (0.2 hli) |

| Max Parts loj los ua ke los ntawm lub tshuab | 2.2 po x 2.2 po x 0.6 po |

| Sib dhos nto mount connectors | Yog lawm |

| Odd form parts: | Yog, Assembly los ntawm tes |

| LED | |

| Resistor thiab capacitor network | |

| Electrolytic capacitor | |

| Kev sib txawv ntawm cov resistors thiab capacitor (pots) | |

| Qhov (sockets). | |

| Reflow soldering | Yog lawm |

| Max PCB loj | 14.5 po x 19.5 po. |

| Min PCB Thickness | 0.2 |

| Fiducial Marks | Nyiam tab sis tsis xav tau |

| PCB tiav: | 1.SMOBC/HASL |

| 2.Electrolytic kub | |

| 3.Electroless kub | |

| 4.Electroless nyiaj | |

| 5.Dub kub | |

| 6. Immersion tin | |

| 7. OSP | |

| PCB puab | Ib qho |

| Panelized PCB | 1.Tab routed |

| 2.Breakaway tabs | |

| 3.V-Scored | |

| 4.Routed + V tau qhab nia | |

| Kev tshuaj xyuas | 1.X-ray tsom xam |

| 2.Microscope rau 20X | |

| Rov ua dua | 1.BGA tshem tawm thiab hloov chaw nres tsheb |

| 2.SMT IR rework chaw nres tsheb | |

| 3.Thru-qhov rework chaw nres tsheb | |

| Firmware | Muab cov ntaub ntawv programming firmware, Firmware + software installation cov lus qhia |

| Kev xeem ua haujlwm | Qib xeem yuav tsum tau nrog rau cov lus qhia xeem |

| PCB cov ntaub ntawv: | PCB Altium / Gerber / Eagle cov ntaub ntawv (nrog rau specs xws li thickness, tooj liab thickness, solder mask xim, tag, thiab lwm yam) |

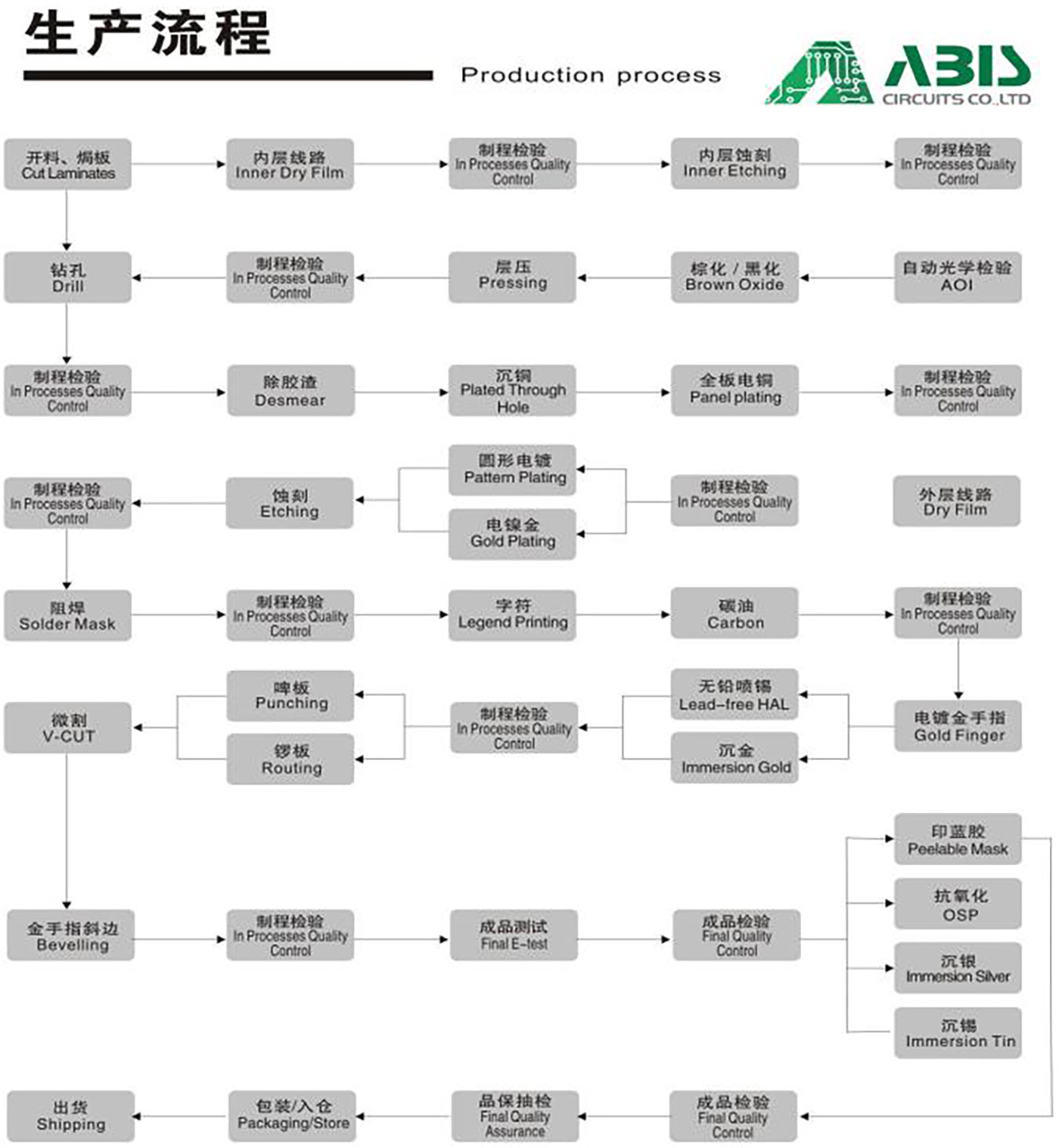

Cov txheej txheem ntau lawm

Cov khoom tau txais → IQC → Tshuag → Khoom siv rau SMT → SMT Line Loading → Solder Paste / Glue Printing → Chip Mount → Reflow → 100% Visual Inspection → Automated Optical Inspection (AOI) → SMT QC Sampling → SMT Tshuag → Khoom siv rau PTH Kab Loading → Plated through Hole → Wave Soldering → Kov Up → 100% Visual Inspection → PTH QC Sampling → In-Circuit Test (ICT) → Final Assembly → Functional Test (FCT) → Packing → OQC Sampling → Shipping

Kev Tswj Xyuas Zoo

| AOI Test | Kos rau solder paste Txheeb xyuas cov khoom siv qis rau 0201 Tshawb xyuas cov khoom uas ploj lawm, offset, qhov tsis raug, polarity |

| X-Ray Inspection | X-Ray muab kev soj ntsuam siab ntawm: BGAs / Micro BGAs / Chip nplai pob khoom / Bare boards |

| Hauv-Circuit Testing | Hauv-Circuit Testing feem ntau yog siv nrog AOI txo qis kev ua haujlwm tsis zoo los ntawm cov teeb meem cuam tshuam. |

| Lub zog-up Test | Advanced Function Test Flash Device Programming Kev kuaj ua haujlwm |

IOC tuaj xyuas

SPI solder paste soj ntsuam

Online AOI tshuaj xyuas

SMT thawj tsab xov xwm tshuaj xyuas

Kev ntsuas sab nraud

X-RAY-welding soj ntsuam

BGA ntaus ntawv rework

QA soj ntsuam

Anti-static warehousing thiab xa khoom

Daim ntawv pov thawj

FAQ

Txhua tus neeg siv khoom yuav muaj kev muag khoom los tiv tauj koj.Peb lub sijhawm ua haujlwm: AM 9:00-PM 19:00 (Beijing Time) txij hnub Monday txog Friday.Peb yuav teb koj email sai li sai tau thaum lub sijhawm ua haujlwm.Thiab koj kuj tuaj yeem tiv tauj peb cov muag khoom hauv xov tooj yog tias ceev.

Daim nqi ntawm cov ntaub ntawv (BOM) nthuav dav:

a), Manufacturers qhov chaw naj npawb,

b), Cov khoom lag luam cov khoom siv tus lej (xws li Digi-key, Mouser, RS)

c), PCBA qauv duab yog tias ua tau.

d), Quantity

ISO9001, ISO14001, UL USA & USA Canada, IFA16949, SGS, RoHS daim ntawv qhia.

Tsis yog, peb ua tsis tautxaisduab cov ntaub ntawv, yog tias koj tsis muajGerbercov ntaub ntawv, koj tuaj yeem xa peb cov qauv los luam nws.

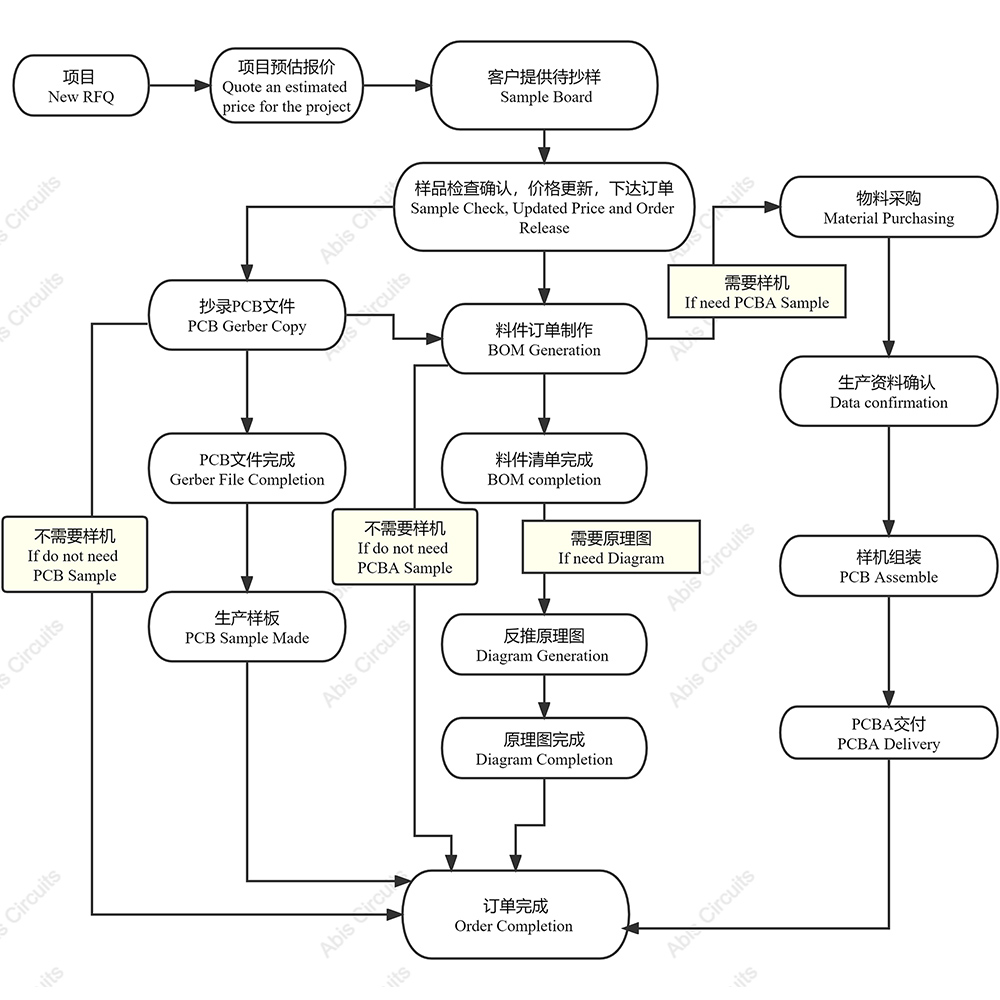

PCB & PCBA Copy Process:

Peb Cov Txheej Txheem Ua Haujlwm Zoo raws li hauv qab no:

a), Kev tshuaj xyuas qhov muag

b), Flying probe, fixture tool

c), impedance tswj

d), Solder-muaj peev xwm nrhiav tau

e), Digital metallograghic microscope

f), AOI (Automated Optical Inspection)

ABLS ua 100% kev pom thiab AOl tshuaj xyuas nrog rau kev ntsuas hluav taws xob, kev ntsuas hluav taws xob siab, ntsuas kev tswj xyuas impedance, micro-sectioning, thermal shock test, solder test, kev ntseeg siab, kev ntsuas kev tiv thaiv insulating, ionic cleanliness test thiab PCBA Functional testing.

ABIS muaj ib pab neeg ua haujlwm rau kev pab cuam tom qab muag.Yog tias muaj teeb meem tom qab cov khoom muag, koj tuaj yeem tawm tswv yim rau kev muag khoom.Peb yuav teb koj thiab daws nws sai li sai tau thaum peb tau txais koj qhov kev sib cuag.

ABIS muaj kev ntseeg siab heev hauv peb cov PCB thiab PCBA boards, tag nrho cov khoom thiab cov khoom siv yog qhov zoo tshaj plaws thiab qub, cov neeg siv khoom tsis txaus siab yog tsawg heev.

Tus nqi xa khoom raws sijhawm yog ntau dua 95%

a), 24 teev ceev tig rau ob sab qauv PCB

b), 48hours rau 4-8 khaubncaws sab nraud povtseg PCB

c), 1 teev rau kev hais lus

d), 2 teev rau cov lus nug engineer / Cov lus tsis txaus siab

e), 7-24 teev rau kev txhawb nqa kev pabcuam / xaj kev pabcuam / kev tsim khoom lag luam